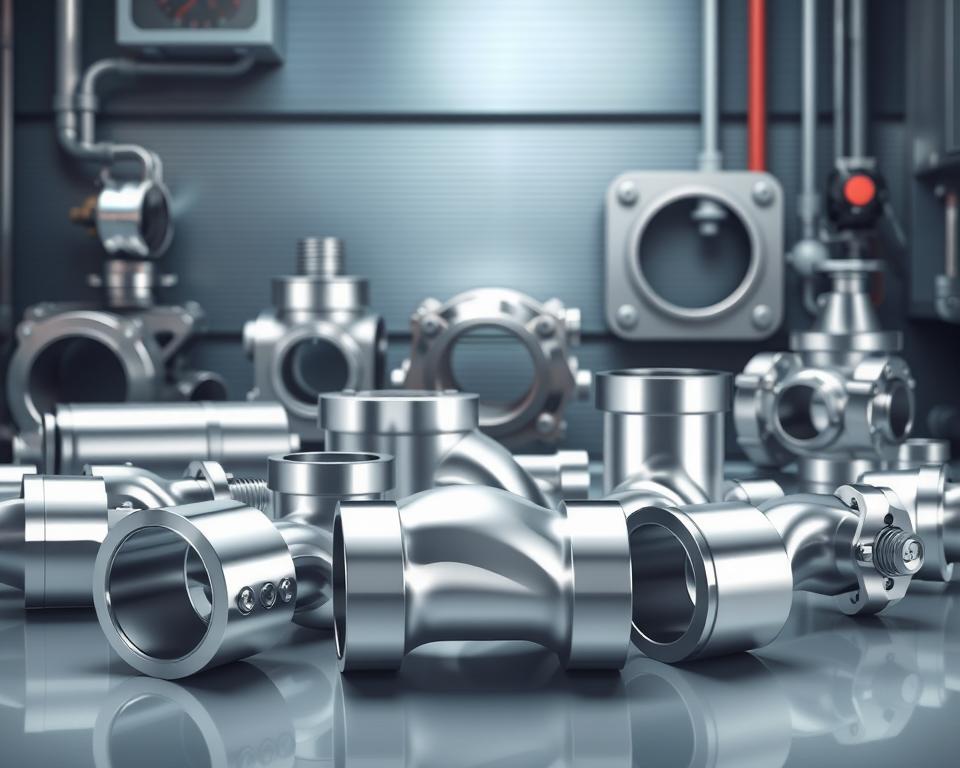

High-End Tri-Clamp-Style Sanitary Connectors for Ultra-Clean Operations

In settings where cleanliness saves lives, even sub-visible crevices count. That’s why, companies like Installation Parts Supply deliver exactingly crafted solutions designed to eliminate risks. Such hygienic connection systems merge durability with effortless setup, positioning them as a top choice for sites that insist on flawless results.

These fittings aren’t just about preventing leaks – they’re crafted for the tough requirements of food-grade production, brew operations, and pharmaceutical manufacturing. Made from rust-proof metals, they endure repeated washdowns while sustaining durability. The engineering ethos parallels industry leaders like Alfa Laval, placing first sanitary coupling smooth surfaces and swift teardown.

How do these connectors stand out? Think one-handed installation and tool-free maintenance. Operators value the straightforward build during high-pressure runs, while managers favor uniformity across pipelines. Every piece receives strict quality checks to satisfy FDA and 3-A Sanitary Standards.

Central Ideas

- Adopted by industry pros for airtight reliability in mission-critical zones

- Constructed with premium stainless steel for long-term resilience

- Facilitates following food safety and pharmaceutical codes

- Reduces downtime through hand-tightened buildup and cleaning

- Supported through QA systems equalling global benchmarks

Component Synopsis and Major Gains

Reliable connections are the backbone of contamination-free operations. Installation Parts Supply develops components that merge high-precision build with real-world usability. Their offerings supply tight containment while making upkeep easy—critical for industries where efficiency meets cleanliness.

Premium Build & Sanitary Ratings

Every component faces intensive trials to hit worldwide standards. The substrates oppose oxidization, even after repeated sterilization cycles. Fluid-tight rings halt microbe spread, a feature valued by dairy processors and pharmaceutical manufacturers alike.

These components mirror the standards of leaders like Alfa Laval, guaranteeing smooth surfaces and uniform dimensions. Adaptable setups adapt to existing setups, reducing retrofit costs. Workers see 30% speedier setups compared to traditional threaded systems.

Why Choose This Supplier

Bespoke machining sets this supplier apart. Need a unique angle or specialized finish? Their team teams up with buyers to engineer tailored solutions. Quick shipment and 24/7 technical support sustain throughput.

The perks reach beyond lifespan. Tool-free disassembly slims idle time during cleanliness checks. Brew houses using these connectors note fewer production stoppages and even output. It’s not just about hitting the rules—it’s about leapfrogging requirements.

Design Highlights & Technical Notes

Exact machining marries adaptability in modern industrial systems. Installation Parts Supply builds components that harmonize stringent tolerances with versatile designs. Their mode ensures smooth fitment into running equipment while maintaining rigorous sanitary rules.

Bespoke Metals & Finishes

Specific processes call for tailored gear. That’s why grades available run 304 to 316L, chosen due to strength and corrosion resistance. Surface treatments like electro-polish yield mirror-like smoothness, decreasing pathogen grip by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes use laser gauges to guarantee uniform wall thickness. Fine margins (±0.005″) stop stress points in intense psi zones. During quality checks, components face X-ray scans and pressure tests to identify microscopic flaws.

Personalization surpasses looks. Clients seek custom orientations, flange sizes, or custom coatings for chemical resistance. These custom variants help industries keep pace with changing codes without overhauling the whole plant.

Tri-Clamp Fittings – Setup & Uses

Today’s accelerated sites need fittings that snap in promptly yet work steadily. These joining solutions prove ideal in environments where rapidity intersects sterility. Their design scraps complicated hardware, empowering teams to retain focus on throughput rather than setup struggles.

Simplified Assembly Process

Coupled flange rims and a centered gasket establish perfect seals in seconds. Operators fit the parts, insert the hinged clamp, and seal by hand – no wrenches required. This process lowers setup slips while keeping even compression across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Convertible Connections for Gear

Linking sanitary lines and machines, these interfaces link unlike gear seamlessly. The uniform design couples with various diameters, allowing quick reconfigurations during product changeovers. Dairy plants regularly utilize them to alternate between cleaning cycles and production runs smoothly.

Upkeep units favor how components disassemble for thorough sanitation. Smooth surfaces halt grime collection, while the thread-free design banishes germ traps. Weekly cleanings require 50% less effort compared to older connection methods.

Sector Uses & Regulatory Alignment

Covering brewpubs to immunization facilities, modern facilities depend on parts that adapt to diverse needs while meeting exacting rules. Installation Parts Supply delivers solutions used across high-stakes domains where product purity must be absolute. Their designs tie output to standards, crafting assemblies that thrive under demand.

F&B plus Pharma Fields

In food and beverage plants, quick-change connections streamline hopping from batch to CIP. Breweries utilize tri-clover tees to manage complex flow paths with zero blend danger. Pharmaceutical manufacturers trust leak-free closures to guard delicate ingredients during sterile transfers.

These links come in multiple sizes to match piping layouts, from small-scale laboratories to mega fermenters. Dairy processors value how standardized parts minimize stoppages during equipment upgrades. Even minor tweaks in production processes are absorbed through modular designs.

Meeting ASME, ISO & 3A Rules

Every component achieves and goes beyond benchmarks set by global organizations. ASME-certified materials manage hot media in pasteurization systems, while ISO-compliant finishes prevent bacterial buildup. The 3-A symbol confirms appropriateness for direct contact with consumables.

Tri-Clamp couplings embody this pledge. Their uniform dimensions ensure leak-free performance across automated lines. Third-party audits validate supply chain from raw materials to finished goods, providing inspectors certainty.

By staying within these codes, facilities simplify audits and earn approvals quickly. It’s not just about sidestepping fees—it’s about securing customer faith through transparent sanitation.

Closing Thoughts & Action Plan

Opting for fittings that link efficiency with standards drives facility results. Installation Parts Supply delivers systems blending strength and sanitation, granting leak-free performance across food, pharma, and beverage environments. Their products conform to rigorous standards while making daily work simpler through simple fitment.

With variants in steels and textures, solutions adapt to unique process requirements. Whether handling high-temperature fluids or regular CIP runs, material choices and surface treatments enhance life cycle. Professionals value the wide selection of connection types tailored to set velocity and line pressure.

Ordering proves straightforward, with expert guidance available to fit plant specs. Fast shipment and minimized wait times minimize downtime during upgrades or replacements. Regular service becomes effortless thanks to snap-apart unions and slick interiors that fight fouling.

Looking to improve operational trust? Speak with Installation Parts Supply to discover custom layouts – from tri-clamp to tri-clover designs – backed by industry-leading quality assurance. Their team makes sure you satisfy today’s rules while preparing for tomorrow’s challenges.